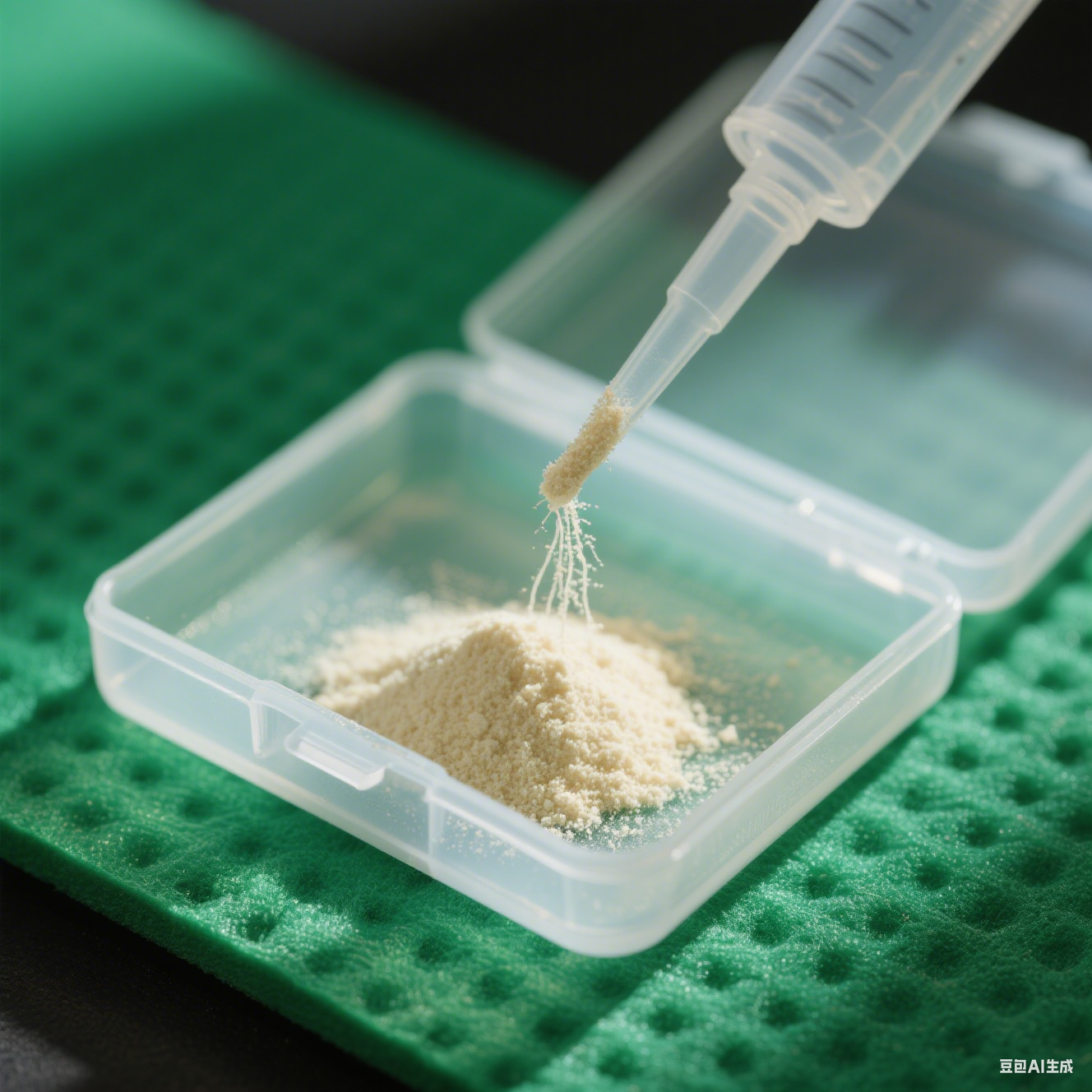

maltitol factory

A maltitol factory represents a state-of-the-art manufacturing facility dedicated to producing this versatile sugar alcohol sweetener through advanced hydrogenation processes. The facility encompasses multiple production zones, including raw material handling, catalytic hydrogenation units, purification systems, and sophisticated packaging lines. At its core, the factory utilizes high-pressure hydrogen reactors where maltose is converted into maltitol under carefully controlled conditions. Modern maltitol factories feature automated control systems that monitor and adjust critical parameters such as temperature, pressure, and reaction time to ensure consistent product quality. The facility incorporates advanced filtration and crystallization units that ensure the final product meets strict purity standards. Quality control laboratories equipped with analytical instruments continuously monitor production parameters and product specifications. The factory's design typically includes energy-efficient systems, water recycling capabilities, and environmental control measures to minimize its ecological footprint. With an integrated warehouse management system, the facility efficiently handles both incoming raw materials and outgoing finished products, maintaining optimal inventory levels and ensuring timely delivery to customers. The factory's production capacity can be scaled to meet varying market demands, while maintaining strict adherence to food safety standards and regulatory requirements.