china maltitol manufacturers

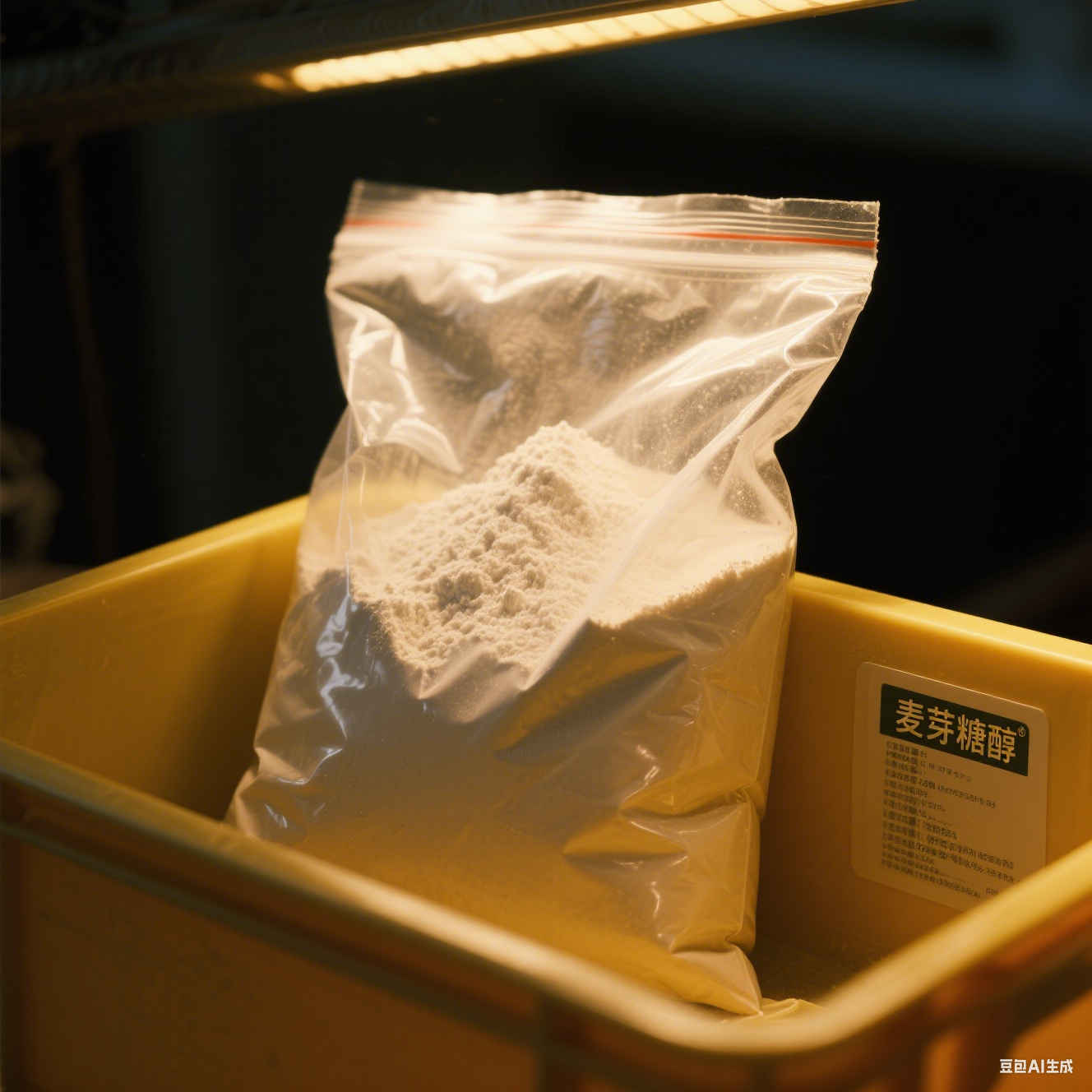

China maltitol manufacturers have established themselves as global leaders in producing this versatile sugar alcohol sweetener. These manufacturers employ advanced production technologies and strict quality control measures to create high-quality maltitol products that meet international standards. The manufacturing process involves the hydrogenation of maltose derived from starch, resulting in a crystalline powder that serves as an excellent sugar substitute. These facilities are equipped with state-of-the-art machinery and automated systems that ensure consistent product quality and efficient production cycles. Chinese manufacturers have developed sophisticated purification techniques that yield maltitol with 99% or higher purity levels, making it suitable for various applications in the food and pharmaceutical industries. The facilities typically feature integrated production lines that handle everything from raw material processing to final product packaging, maintaining product integrity throughout the manufacturing process. These manufacturers also implement comprehensive quality management systems that comply with ISO standards and Good Manufacturing Practices (GMP), ensuring their products meet international safety and quality requirements. Their production capabilities range from small batches to large-scale industrial quantities, allowing them to serve diverse market needs efficiently.