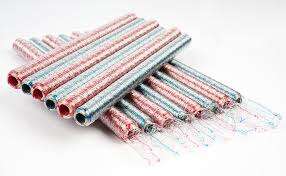

cellulose casing

Cellulose casing represents a revolutionary advancement in food packaging technology, particularly in the meat processing industry. This innovative casing is manufactured from natural cellulose fibers, processed through advanced chemical treatments to create a robust, uniform, and food-safe packaging solution. The casing exhibits exceptional permeability characteristics, allowing optimal smoke penetration and moisture control during the cooking and smoking processes. Its standardized diameter and thickness ensure consistent product appearance and cooking performance. The material's inherent strength supports high-speed production capabilities while maintaining structural integrity throughout processing. Cellulose casings are particularly valued for their versatility in various applications, from fresh sausages to processed meat products. They demonstrate remarkable stability during both hot and cold processing conditions, maintaining their shape and protecting the product integrity. The casing's surface properties facilitate easy peeling and excellent printability for branding purposes. Environmental considerations are addressed through the casing's biodegradability, aligning with modern sustainability requirements. The manufacturing process ensures uniform wall thickness and diameter control, critical for automated processing systems and consistent final product quality.